Sheets vs. Pages

Paper Stock Grade, Finish, & Weight

Paper Coatings

Aqueous & UV Coating

Collating & Slip Sheeting

Sheets vs. Pages:

How are the number of pages in a document counted?

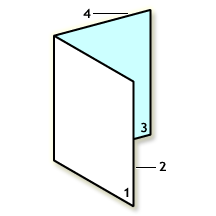

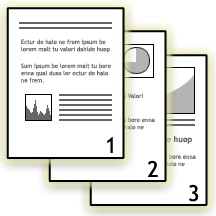

Sometimes there is confusion about the difference between what is a sheet of paper and what is a page. They are not the same. For example, the booklet on the left has two sheets of paper that are folded and saddle stitched (stapled) along the fold, joining together the folded sheets. This booklet contains eight pages.

The images below show how the printing industry counts the number of pages in a document. If you have questions about the number of pages in your project, use Contact Us in the menu above.

Sheets vs. Pages Illustration

One Sheet, Two Pages A single sheet of paper has two sides. Each side is considered one page. So a sheet of paper is two pages. |  One Sheet Folded, Four Pages A sheet folded in two is a four page document. Page one is the front cover, page two is the inside front, page three is the facing page, and page four is the back cover. |  Two Folded Sheets, Eight Pages Two folded sheets that are nested together are an eight page document. |

Back to Top

Paper Stock Grade, Finish, & Weight:

What is the difference between Text, Book, Bond, Offset, Cover, Bristol, Index, Tag, and Card paper?

Paper can be grouped into two main grades based on weight and thickness: Text and Cover.

"Text" is a generic name for a variety of lighter, thinner paper stocks that includes Book, Bond, Writing, Ledger, Offset paper. Text paper is flexible, can be easily rolled and folded and is used for printing flyers, handouts, letterheads, book pages, etc. The paper used in ink jet printers would be considered Text.

"Cover" is a generic name for a variety of heavier and thicker paper stocks that includes Bristol, Index, Tag, and Card paper. It is more durable than Text paper. Cover paper is more rigid and must be scored (i.e., dented or creased) before it can be folded. This type of paper is usually smooth, but can have a texture. It can have either a matte or glossy appearance. Cover/Card stock is often used for mass mailed postcards, business cards, playing cards, invitations, program covers, greeting cards, door hangers, catalogue covers, presentation covers, scrapbooking, etc. At its heaviest, Card stock would be similar to material used for a cereal box.

What's the difference between gloss and matte paper?

Paper with a gloss finish is smooth and shiny while matte paper is flat with little or no shine. Gloss stock makes colors look smoother, deeper, richer, with great color-contrast. Photo's and graphics tend to look better on gloss stock, while text heavy documents and artwork are often use matte stock.

Text is more easily read on paper with a matte finish. The softer looking dull surface of matte paper provides color contrast and clarity. Unlike glossy paper, matte stock is more forgiving of fingerprints, smudges and dust.

What's the difference between lb, #, gsm, g/m2 and g/m2?

Besides a generic "Text" weight or "Cover" weight, descriptions often include a number to refer to the weight of the paper. The higher the number, the heavier the paper. Heavier paper is typically thicker as well.

There are two systems for indicating the weight of paper; an international metric system and a North American system. The North American system for paper weight uses pounds (expressed as either # or lb) while the metric system uses grams per square meter (gsm or g/m2 or g/m2), often called "grammage". The North American pound rating is based on the weight of 500 sheets (a.k.a. a ream), while the metric rating is based on the weight of a 1 meter by 1 meter sheet.

The U.S. system is a bit confusing because the same pound number can be used for both lighter (Text) paper and heavier (Cover) paper. For example, 80# Text paper and 80# Cover paper have the same pound number even though the Cover stock is almost twice as heavy! The metric system in comparison is more straight forward. For example, 80# Text Paper weighs 104 g/m2 while 80# Cover Stock weighs 218 g/m2. The Cover stock is clearly more than twice as heavy as the Text stock.

The reason actual weight of Text and Cover stock of the same pound rating will be different is due to the way the pound rating is determined. Both use the weight of 500 sheets for the pound rating, but they use a different size sheet. For Text stock, 500 sheets measuring 25" x 38" are used. While for Cover stock, 500 sheets measuring 20" x 26" sheets are used instead.

Sometimes I see "10 pt" or "12 pt" paper stock listed. Is this a paper weight?

Sometimes the thickness of Cover/Card stock is used instead of its weight. In North America, paper thickness can be displayed in points (1/1000" or .001"). For example, a 10 pt. Card stock is 0.010" thick (about the weight of a 140lb Index stock) while 12 pt. Card stock is 0.012" thick (about the weight of a 100lb Cover stock).

Paper Weight Comparison Chart (lightest to heaviest)

| #'s | gsm | Paper Stock |

| 16lb | 60.2 g/m2 | Bond/Writing/Ledger |

| 40lb | 60.2 g/m2 | Book/Text/Offset |

| 20lb | 75.2 g/m2 | Bond/Writing/Ledger |

| 50lb | 75.2 g/m2 | Book/Text/Offset |

| 24lb | 90.3 g/m2 | Bond/Writing/Ledger |

| 60lb | 90.3 g/m2 | Book/Text/Offset |

| 80lb | 104 g/m2 | Book/Text/Offset |

| 28lb | 105.4 g/m2 | Bond/Writing/Ledger |

| 70lb | 105.4 g/m2 | Book/Text/Offset |

| 40lb | 109.1 g/m2 | Cover |

| 50lb | 135.5 g/m2 | Cover |

| 60lb | 161.8 g/m2 | Cover |

| 100lb | 161.8 g/m2 | Tag |

| 90lb | 161.8 g/m2 | Index |

| 65lb | 176.8 g/m2 | Cover |

| 110lb | 199.4 g/m2 | Index |

| 80lb | 218.2 g/m2 | Cover |

| 90lb | 244.6 g/m2 | Cover |

| 140lb | 252.1 g/m2 | Index |

| 100lb | 270.9 g/m2 | Cover |

| 170lb | 308.5 g/m2 | Index |

| 220lb | 385.1 g/m2 | Index |

Back to Top

Paper Coatings:

Choosing the right paper stock or coating for your project is important to achieve the desired result.

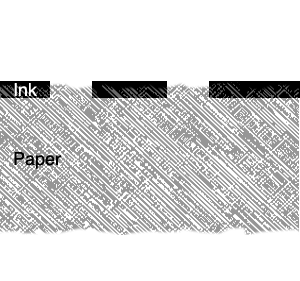

What is uncoated paper?

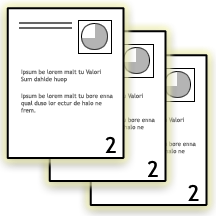

Exaggerated Side View Illustration | All paper stocks start out being uncoated. Uncoated paper is porous with an uneven, rougher surface. As a result, uncoated paper is easier to write on as it absorb ink readily and dries to the touch faster. However, the heavier amount of ink uncoated paper absorbs may result in less rub resistance. Uncoated stocks include bonds, offsets, card, and newsprint. |

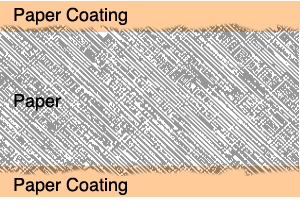

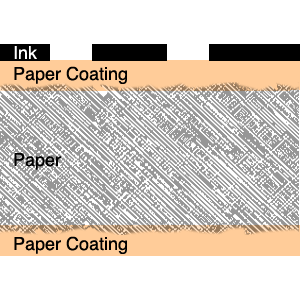

What is coated paper?

Exaggerated Side View Illustration | After manufacture, the uncoated paper surface may be coated with white clay materials. The clay gives the paper a smooth feel by filling minute valleys in the paper surface. The coating also limits the absorption of inks into the paper. Because the inks stay on the surface of the coating instead of soaking in, the ink looks deeper, sharper and glossier. However, writing and ballpoint pen inks may take longer to dry on coated paper and can smudge more easily. On coated stock, less ink is need to achieve the desired visual richness for text, images and photo's.

Coatings are offered in a range of reflectivity values including dull, matte, silk, satin or glossy. Reading long areas of text is easier when printed on dull or matt finishes. After printing images on dull or mat stock, a varnish can be applied to the picture areas to add gloss and make the pictures pop. |

What's the difference between coated and uncoated paper?

Paper with a coating is smooth and shiny while uncoated paper is flat with little or no shine. Gloss stock makes colors look smoother, deeper, richer, with great color-contrast. Photo's and graphics tend to look better on gloss stock, while text heavy documents and artwork are often use matte stock.

Text is more easily read on paper with a matte finish. The softer looking dull surface of matte paper provides color contrast and clarity. Unlike glossy paper, matte stock is more forgiving of fingerprints, smudges and dust.

Uncoated paper is very absorbant, and ink dots will tend to spread outwards (i.e., dot gain), leading to a less precise and darker image than when printed on coated stock. A similar effect happens when a paper towel is placed on a spilled drop of coffee. The drop diameter increases and gets a ragged edge as the liquid spreads in the absorbant fibers. This dot gain can be minimized using sophisticated printing techniques, but it can't be eliminated. Coated paper is less absorbant and therefore dot gain is usually not an issue.

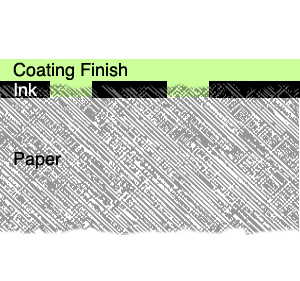

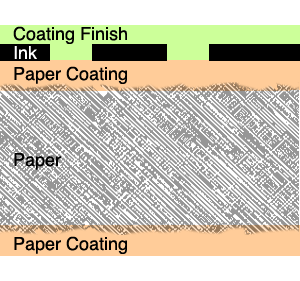

What's the difference between coated paper and a coating finish?

A coated paper is produced at the paper mill with a smooth surface and can have a range of reflectivity values including dull, matte, silk, satin or glossy. A coating finish on the other hand is a clear layer applied after the ink is printed on the paper. It is used to enhance the visual appeal of printed graphics or to add durability and protection to the printing.

What is uncoated finishing?

A protective coating or varnish will not be applied to the printed piece.

|  |

Exaggerated Side View Illustration Printed paper, no finishing coat. | Exaggerated Side View Illustration Printed coated paper, no finishing coat.

|

What is coated finishing?

Coating finishes are applied after the ink. They are often used to enhance the appearance of graphics. These coatings also protect the printed surface from scratching, marring, fingerprints and dirt by increasing the rub and scuff resistance.

Coating finishes improve durability of the printed pieces during shipment through to the end use of items such as postcards, brochures, catalog covers, flyers. Coating finishes can also be used on enhance economy-grade paper by improving gloss and providing a smoother touch.

|  |

Exaggerated Side View Illustration Uncoated paper printed, with coating finish. | Exaggerated Side View Illustration Coated paper printed, with coating finish.

|

Back to Top

An aqueous coating is a water-based coating applied to a printed piece to enhance the graphics with a matte or gloss finish and to provide added durability and protection. Aqueous coatings provide good rub and scuff resistance. Like other finishes applied to printed paper, it protects the surface from scratches, fingerprints, dirt, and smudging.

What's the difference between an aqueous coating and traditional varnish?

Aqueous coatings are less costly than varnish. Aqueous coatings are dried in minutes while a traditional varnishes may need a few hours or days to dry. Aqueous coatings don’t yellow with age while varnishes will yellow.

What's the difference between an aqueous coating and UV coating?

Aqueous coatings are dried by hot air, UV coatings are almost instantly dried and cured by ultraviolet light. UV coatings are tougher and more slippery than aqueous. A ballpoint pen can be used to write on an aqueous coating, but not on most UV coatings. UV coatings can achieve a higher gloss.

What is UV coating finishing?

A matte, silk, satin or glossy finish is applied to the entire printed piece. For this type of coating a liquid is applied to the printed paper and exposed to an ultraviolet light which rapidly cures it and bonds it to the paper. UV coating adds durability to the printed piece and deters dirt. For most UV coatings, the piece can no longer be printed on nor written on with a ballpoint pen.

What is spot UV finishing?

A matte, silk, satin or glossy finish can be applied to specific "spot" areas of the printed piece such as photographs and graphic images. For this type of coating a liquid is applied to the printed paper and exposed to an ultraviolet light which rapidly cures it and bonds it to the paper.

Our online printing store may include options to have the pages of the finished document collated. Or, we may require that pages be laid out in a way that facilitates collating the pages during production. Examples of printed items that are often collated include brochures, books, booklets, manuals, copies, and pamphlets.

Back to Top

What is collating?

| In printing, collating refers to sequentially layering the pages of a multiple page document, book, brochure, etc. in their proper, finished order. Collation is performed during the finishing process. It is often followed by binding the pages together. The simplest example of collating is a three page document, where page one is followed by page two, which is followed by page three. This is the same sequence the pages are read. |

What is reverse collating?

| Instead of sequencing the pages where page one is followed by page two, which is followed by page three, the pages are in reverse order. Page three is first, followed by page two, which is followed by page one. |

What is meant by uncollated?

An option to order a multiple page document without collating (i.e., uncollated), simply means that each page will be delivered in separate stacks or bundles. Page one will be in one stack, page two in other stack, etc.

What is slip sheeting?

| In printing, slip sheeting refers to placing a blank piece of paper between groups of printed pages. It can be used with collated or uncollated pages. Slip sheets make it easy to see where one set stops and another begins, especially when stacked loose one on top of another and packed in cartons. |

Back to Top

We look forward to earning your business every day.